How are stored products identified for each load?

When the order is put together in the marshalling area, all the necessary documentation is filled in. The product details on the various documents, e.g. company, regulatory authorities and shipping agents, must accurately match the ordered product. Otherwise, if the documentation is not perfectly correct, then the products can be rejected at any transfer point on its way to the customer. Therefore, it is absolutely essential to accurately check the load details, before loading is started.

The following checks must be made before loading:

- load temperatures

- order segregation

Load temperature checks

The product sent must be at, or below, the required load out temperature. The temperature must be constantly maintained so temperature fluctuations do not occur.

Chilled product temperature check

The AS 4696:2007 Australian Standard for the hygienic production and transportation of meat and meat products for human consumption requires that the:

- surface temperature of chilled carcases at load out is not more than 7°C

- refrigeration facilities for the chilling of product, other than carcases, maintain the product temperature at not more than 5°

Frozen product temperature check

Before loading, this check must be done to make sure the product’s temperature meets regulations. For example, frozen product in export cartons must have a temperature of -10°C or less at load out.

How temperatures are checked has been covered in the training materials for AMPA2109 Store carcase product and AMPA2110 Store carton product.

Temperature testing is essential, as any time out of refrigeration can raise the meat temperature leading to increased bacterial growth and food spoilage. Therefore, when product is to be moved from refrigeration storage as part of a load, it should be held under refrigeration until everything is ready for loading. That is, the transport must be ready for loading, be clean and have a refrigeration unit ready to maintain the product temperature during transit. This may mean the product, which is sorted into lots in the load out area and consolidated, is then stored in a holding chiller until it can be loaded.

The relevant requirements in the AS 4696:2007 Australian Standard for the hygienic production and transportation of meat and meat products for human consumption, are summarised in the table below.

|

|

Load out | During transportation |

| Carcase

|

Leaves chillers at a surface temperature of 7°C | The transport must maintain its air temperature at 10°C |

| Product other that carcase | Leaves chillers at a temperature of less than 5°C | The transport must maintain its air temperature at 10°C |

Order segregation

The product you are loading will have been demarcated or separated during marshalling. This demarcation has to be maintained during loading. This is to make sure the right product is delivered to the right place or customer.

Pallets should have been stacked or product arranged into lots according to their order documents and the workplace procedures. This separation of all lot types must be maintained so identity is not mixed up. Export and domestic product must be separated throughout preparation, transport and storage, e.g. by a physical barrier.

Specification checks

Specification checks should have been made when the order was compiled. Product checks are also often part of the workplace procedures and job descriptions of load out workers. This is because out-of-specification products may be identified during loading.

The specifications which need to be checked include:

- trade description

- weight

- packaging defects

- temperature

- storage requirements

- brands and labels.

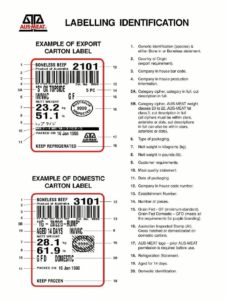

Carton label with details

© AUS-MEAT Limited 2001

Carcase loadout photo