What hygiene and sanitation requirements apply in the load out areas?

Load out and loading areas associated with chillers and freezers must be enclosed to prevent contamination of products. Personal hygiene requirements are set out in the work instructions and relevant Standard Operating Procedures (SOP). It is vitally important all out of specification packaging is reported and not allowed to leave the plant.

Electronic system in the meat industry?

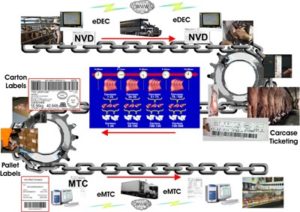

The red meat supply chain has adopted the GS1(Australia is a not-for-profit organisation that locally administers the global multi-industry system of identification and communication for products, services, assets and locations – the GS1 System) standards for numbering, bar coding and electronic messaging for specific red meat supply chain activities such as:

- carton labelling

- carcase ticketing

- pallet labelling

- electronic messaging for National Vendor Declarations (eDEC)

- Electronic Meat Transfer Certificates (eMTC).

Many meat processing plants have commenced introducing these electronic systems. Therefore meat processing workers need not only be aware these systems exist, but also of the responsibilities associated with their daily work.

The diagram below shows the red meat supply chain and identifies each of the activities, what the relationship is of each of the activities and their respective importance along the supply chain.

The implementation is being coordinated by the Red Meat Supply Chain Committee. To date the committee has produced the Australian Red Meat Numbering and Bar coding guidelines for non-retail meat products, Message Implementation Guidelines, technical fact sheets, case studies, interactive CDs and a cost benefit analysis relating to project outcomes.

What are Variable Weight Carcase labels?

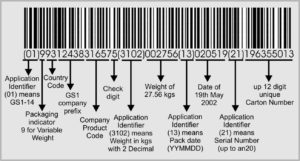

Australian red meat industry standard Variable Weight Carcass Labels use bar code symbology known as GS1-128.

The GS1-128 Bar Code Symbol allows primary item identification and secondary attribute information to be represented in the bar code. Application Identifiers (AIs) effectively act as prefixes for this information and define the meaning and structure of the embedded data which follows.

The system also allows a processor to represent attribute information such as weight, slaughter date and serial numbers in a standard format. This ensures the attribute information encoded by one company can also be scanned and interpreted by any other company in the supply chain.

An example of a carcase label appears below.

What is a Variable Weight Carton Label?

The Australian red meat industry Standard Variable Weight Carton Label uses bar code symbology known as GS1-128. The GS1-128 bar code allows primary item information and secondary attribute information to be represented in the bar code. Application Identifiers (AIs) effectively act as prefixes for this information and define the meaning and structure of the embedded data.

GS1 Australia allocates a parcel of numbers to member companies. These numbers include a GS1 Company Prefix to identify the company and a range of numbers to identify products (which members themselves allocate sequentially), followed by a Check Digit which is mathematically calculated to verify the details of the GS1 number (GTIN).

The system also allows the meat processor to represent attribute information such as batch numbers, serial numbers, expiry dates and weight in a standard format. This ensures the attribute information encoded by one company can also be scanned and interpreted by any other company in the supply chain.

Below is an example of a carton label.