Auditing

What is an Audit?

Auditing is a planned review of a quality system to check that what the company says it does in the Quality Manual, is what is being done in the plant.

What are auditors looking for?

Auditors are looking to make sure:

- workers are following standard operating procedures and work instructions

- monitoring is being done properly and recorded

- corrective action is documented happens when a deviation occurs

- workers understand their responsibilities and duties.

If an auditor finds evidence of the quality system not working, that is workers are not following procedures – a non-conformity – then the auditor will issue a corrective action request (CAR). This tells the company what is wrong and what has to be changed. Auditors must return and check CARs have been carried out.

If too many non-conformities are found or if a very serious non-conformity is found, the licence of the plant could be suspended and the plant closed.

What is an internal audit?

An internal audit is when quality system audits are carried out by employees of the company. Internal audits are done to check the QA system is working.

What is an external audit?

External audits in the meat industry can be carried out by different agencies or companies. In domestic works the quality system is audited by the state meat authority or a company working on its behalf. For example, SGS audits on behalf of Prime Safe in Victoria.

Export works are audited by Department of Agriculture officers. Export works are also reviewed by representatives of the government of importing countries. These include United States or European Union. Both export and domestic sheds with AUS-MEAT registration are audited against their AUS-MEAT quality system.

Many of the larger corporate customers such as Woolworths, Coles and McDonalds also conduct external audits against their specific company specifications.

External audits are important because a critical non-conformity can lead to the immediate suspension of a company’s licence to process meat.

What is the role of the worker in an audit?

It is important that you perform your duties according to the SOPs and work instructions for the task or job being done.

If you are questioned by an auditor you should be truthful. Do not guess the answer. If you don’t fully understand the question, ask the question to be explained to you. If you still don’t understand ask your supervisor what the auditor is asking you.

Electric systems in the meat industry

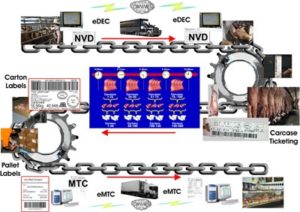

The red meat supply chain has adopted the GS1 (1) standards for Numbering, Bar coding and Electronic messaging for specific red meat supply chain activities such as:

- carton labelling

- carcase ticketing

- pallet labelling

- electronic messaging for National Vendor Declarations (eDEC)

- Electronic Meat Transfer Certificates (eMTC).

Many meat processing plants have commenced introducing these electronic systems. Therefore meat processing workers need not only be aware that these systems exist, but also of the responsibilities associated with their daily work.

The diagram below shows the red meat supply chain and identifies each of the activities, what the relationship is of each of the activities and their respective importance along the supply chain.

The implementation is being coordinated by the Red Meat Supply Chain Committee. To date the committee has produced the Australian Red Meat Numbering and Bar coding guidelines for non-retail meat products, Message Implementation Guidelines, technical fact sheets, case studies, interactive CDs and a cost benefit analysis relating to project outcomes.