How is the knife maintained in good order?

Your knife must be kept sharp at all times. This will reduce the risk of an accident and ensure more efficient use and reduce repetitive strain injuries. Grinding stones, oilstones and machine sharpening are used to sharpen the blade, eliminate the shoulder and achieve the most efficient blade bevel.

You must use your knives skilfully and safely.

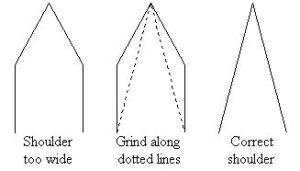

Before the knife edge can be sharpened, you must decide what shape the blade is to be. This depends on its shoulder and bevel. The thicker the shoulder, the greater the angle of the bevel. Thicker shoulders are useful when cutting around bones or thick wool as they minimises the edge being ‘rolled over’, which would then require steeling. A rough steel may be required to straighten the edge after contact with bones / thick wool or the like.

If the blade is too thick or has large shoulders, the edge will quickly become dull and will not cut easily.

The bevel

Thick Shoulder Blade too thick

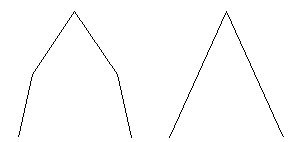

The bevel is the pointed part of the blade and can be a different shape on different knives. There are different shapes of bevel because:

- different tasks need different shapes, e.g. boning, slaughtering

- types of steel vary – hard or soft

- shape of blades vary.

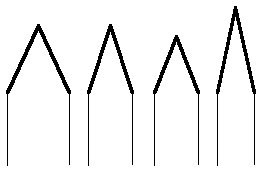

The bevel is shown by the darker lines on the following diagram.

Different bevels on knives

The bevel should be about 1 millimetre wide. Both sides of the blade should have an even bevelled surface at an angle of 15–25 degrees. The two bevels must meet precisely along the full length of the blade. This can be difficult along the curved part of the blade. During the sweeping motion of sharpening, the knife handle will need to be lifted slightly to allow the bevel to continue down the curved blade. The use of a black marker to mark the bevel will enable the user to see where the metal is coming off the knife, and enable the bevel to be even the full length of the blade.

The bevel is different for each type of work. For example, boning knives frequently come in contact with bone. A fine bevel will often result in large chips in the cutting edge, so a thicker bevel is best. Slicing or skinning knives need a fine bevel or hollow grinding to remove resistance or pressure needed to cut.

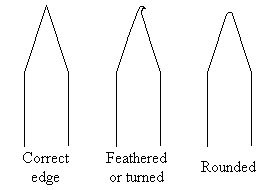

The knife edge

The knife edge is the point where these two bevelled edges meet. The edge will be very thin if both the shoulder and the bevel have been maintained correctly. This can result in the edge turning over and forming a ‘lip’ or ‘feather’. You must take this lip or feather off or the edge will double or sometimes treble in thickness. It will then not cut cleanly.

Types of edges

The grindstone

You should use a grindstone to thin the shoulder of the knife to the desired shape, as shown in the following diagram. A sandstone or emery wheel may also be used for this purpose.