The steel

The steel is used to straighten the edge of the knife. It does not sharpen it. It finishes off and maintains the edge that you achieved by using the grindstone and oilstone.There are many different types of steels, such as:

- smooth – honing should be done with a smooth steel to make as fine an edge as possible

- mild – used to straighten rolled over edges. For best results complete honing back onto smooth steel before recommencement

- coarse – mainly used for straightening severely bent or rolled over edges from cutting into bones or through thick wool and the like. For best results complete honing back onto smooth steel before recommencement

- diamond impregnated – the diamond particles are of a particular shape to ensure optimal honing of the edge, and the steel surface is coated with diamond granules

- wire-styled steel – similar to a smooth steel with set angles to pull the knife through.

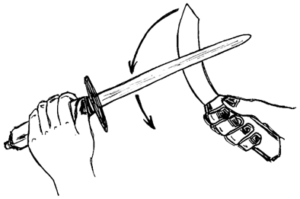

When using the steel, lightly stroke the knife a few times each side is all it should take, on a smooth sharpening steel to restore the shaving edge each time it dulls. This is done by placing the heel of the blade on the steel and lightly drawing the blade down across the steel at the same angle as the bevel. You should always use the same amount of strokes on each side of the blade.

A bad habit many workers develop is to beat the knife on the steel, often resulting in chipped blades. The end of the steel is magnetised – this is all the contact pressure you need. Get into the habit of guiding the blade down the steel gently and slowly’. A steel is only intended to straighten or restore the cutting edge not grind it- that’s what the sharpening stone does!

Thumb on same side as fingers – cut resistant gloves are also recommended

After using the steel you should sterilise the knife. If the edge on the knife has been ‘rolled over’ the use of a rough steel maybe required to straighten the edge prior to using a smooth steel. The rough steel has more bite than a smooth and hence straightens a rolled blade more easily and quickly.

The knife is then ready for use. For safety most employers insist on an aftermarket hand protector fitted to the shaft of the steel. They are mostly made of a rounded piece of cutting board with a hole in the middle; it slides down the shaft to the handle. They are essential for protecting your thumb against cuts whilst steeling. Always watch what you are doing when steeling. Don’t become complacent.

Hand guards

How is sharpening equipment prepared and maintained?

To maintain a good surface on your steel and protect it from becoming a source of contamination, make sure you scrub your steel thoroughly in hot soapy water, then dry it, at the end of production every day. You may also like to coat your steel with vegetable oil at the end of each day. Every day before you use your steel and wherever required by your workplace procedures, sterilise it in the steriliser. Other sharpening equipment such as grindstones and oilstones or whetstones, must also be prepared and maintained in good working order.

Grindstones / sandstones

Make sure that there is a continual supply of water on the sandstone when it is in use. It keeps the stone clean and the blade cool. Check there are no chips or pieces missing from the stone as this can be a safety hazard and can damage your knife when grinding. Also look for hard lumps in the sandstone; they can cause the knife to be bounced off the wheel. Lumps or bumps will require wheel maintenance (cutting down the surface).

Maintain the machine bearing to ensure smooth turning and shape of the stone. High speed grinders are good as long as they are operated properly. Safety is the major concern, so get an expert to demonstrate its use. Heat is the next major concern – the blade must be kept cool. Don’t be tempted to press hard for a quick result. Be patient because if the blade overheats (goes dark or blue) your knife edge is ruined. It will become brittle, chip easily and require all the damaged steel to be carefully removed. Most people find it easier to buy a new knife and start again.

Oilstone (whetstone)

You must clean the oilstone regularly with soap and water and also sterilise it. This will help to prevent micro-organisms building up and will maintain a better surface for honing. Oilstones should be stored correctly to make sure they don’t get contaminated, damaged or stolen.

What are the WHS issues with knives?

Knives are important tools in the meat industry. However, they are also one of the most dangerous utensils if they are not handled and used correctly and safely. The most important thing to remember is that a sharp knife is a safe knife. Blunt knives require more grip and more force to do the job and therefore can result in serious strains and sprains to workers and can cause lasting injuries. Workers with sharp knives do not have to push the knife and therefore get less tired and sore over the course of the day. Likewise a knife that is blunt and has to be forced through the meat is more likely to be accidentally stabbed into the operator themselves or those working around them.

The number of injuries involving knives is a major concern in the meat processing industry. The most common type of injuries are lacerations. These often require medical attention and may need suturing or skin grafting. Avoid injuring yourself with a knife. Common sense and concentration will help you avoid knife accidents. Knife accidents are most likely to occur when you are tired and not concentrating on the job you are doing. It is very easy to cut yourself when you become distracted from your job or careless in your approach to work.

Complacency is a common cause of knife accidents. Workers become so accustomed to handling knives they quickly forget how dangerous they are. Always put knives in your pouch when not in use. Don’t talk with a knife in your hand especially if you ‘talk with your hands’. Don’t use a knife to move pieces of meat, especially to someone else e.g. a slicer to a packer. One slip and you’ve stabbed someone. Don’t use a knife as a scraper.

Injuries include:

- cuts to the non-knife hand or arm (most common)

- cuts to the hand holding the knife which occur when the hand slips off the handle

- cuts which occur with a reverse grip and pulling back towards the body

- cuts to another person, inadvertently, where people are too close together when working

- sprains or strains (e.g. from the extra effort required to use knives that are not sufficiently sharp).