Prior to any non-routine task or ‘high risk’ routine task that does not have a work instruction, there must be an assessment of hazard and risk to the personnel involved, other workers and to the public. A Work Permit and Job Safety Analysis or ‘Take 5’ must be completed and where hazards are identified, the J.S.A. must be documented to include details of the controls to be implemented and the person responsible for implementation identified and recorded.

Generic Tasks

- Maintenance involves many tasks that expose personnel to cuts, burns, hearing & eye hazards. At a minimum safety glasses must be worn by all personnel in the immediate area where grinding or welding is performed. Hearing protection should be worn when in the immediate area of grinding. When handling sharp metal, hot or cold, protective cut resistant gloves should be worn where practical. Isolation of pneumatic electrical and hydraulic powered equipment must be done prior to and work to be performed.

Welding

Arc welding:

- Arc welding must only be performed by personnel who hold a current trade certificate.

Electric arc welding must not be performed where:

- There are other personnel in the immediate area who could be subjected the “arc flash” injury.

- Where the areas are polished stainless-steel surfaces that are unprotected from arc spatter.

- Where there is sandwich styrene panelling that could be subject to hot material.

- Where there is flammable material that could be ignited by sparks.

- P.E. Face shields must be used at all times, and welding curtains deployed so as to eliminate the hazard of “arc flash” to other personnel in the area.

- Welding gloves must be worn.

- Eye protection must be maintained by use of the clear view feature of the welding face shield or safety glasses worn under the shield to avoid material ejected from the hot surface as the face shield is removed.

Gas Welding /Cutting

- Gas welding must only be performed by personnel who hold a current trade certificate that confirms that

- they are competent to perform gas welding / cutting to the standard required by the task

- Gas welding or cutting should only be performed in areas where other personnel are not put at risk from material ejected from the cutting process.

- Gas welding or cutting should not be performed where flammable material can be ignited.

- Gas regulators and hoses and anti-blow back devices and hand pieces should be inspected for damage prior to use.

CARE MUST BE TAKEN NOT TO LEAVE HOT MATERIAL WHERE INJURY OR FIRE MAY RESULT

Grinding

- Care must be taken to direct ejected material away from other personnel and the other personnel in the immediate area are aware that grinding is about to start.

- All personnel engaged in grinding must wear eye protection (goggles) while using any type of grinder.

- Grinding should not take place where sparks are directed toward other personnel, polished or painted surfaces.

- NOTE: 9-inch angle grinders are not to be used onsite unless approved by the Operations or Maintenance Manager after all other tools have been considered and specific SWMS are completed.Hot/Cold Work Permits are required for all Welding and Grinding inside the plant and near any Insulated Refrigeration Panel

Sharpening and Tool Maintenance

- When sharpening & replacing blades on knives, whizz knives, hock cutters, head cutters, band saws, denuders, bible cutters, and blades, all electrical. Pneumatic & hydraulic power must be isolated and cut resistant gloves and eye protection worn at all times.

Lifting

- Manual lifting must not be performed beyond a person’s comfortable capacity, assistance or mechanical aids should be implemented.

- All slings and lifting tackle should be inspected prior to use and W.L.L. must not be exceeded, rigging factors must be estimated and taken into account. A qualified dogger must be engaged to attach slings to any load that requires slings.

- Movement of machinery and steel by means of forklift must be done with extreme caution where steel is in contact with the tynes of the forklift, and load centres taken into account so as to avoid exceeding the capacity of the forklift.

- Any jacking of machinery must be performed using back up packing and no personnel should place hands or fingers under the load.

- Skating of loads must be performed with restraint devices in place before movement of the load where any incline may be encountered

- All personnel not directly involved with movement of loads should be clear of the area.

- Manual lifting Safe manual handling practices must be used at all times, no person should attempt to lift above their comfortable capacity, awkward and heavy objects must be performed as team lifts and only where mechanical assistance cannot be used.

Aerosol Cans

- Many of the aerosol cans used to, clean contacts, lubricate, cleaning etc. have LP gas used as a propellant many are toxic, they should not be used in confined areas or where there is a source if ignition.

Shut Down & Start Up Procedures

- Each area has procedures for start-up and shut down, these procedures must be complied with to ensure safety of all personnel involved in maintenance and production.

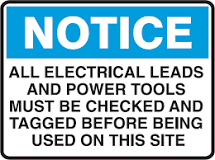

Electrical

- All plug-in leads should be inspected, tested and tagged at regular intervals.

- Leads must be kept off the floor by using stands, care should be taken to ensure that leads do not pass through an area where further hazards can be created.

- Leads must not pass through water or wet areas.

- Power tools should not be used with the switch locked down unless used in conjunction with attachments that require that the switch be locked on.